GeoMelt® vitrification destroys organic wastes and immobilizes radionuclides and heavy metals in an ultra-stable glass.

Vitrification: Durability for Millennia

Vitrification – the process of converting something into glass – has long been considered an ideal choice for high-level nuclear waste by regulators internationally, because of its expected durability over hundreds of thousands of years.

GeoMelt® creates ultra-stable glass that is typically 10 times stronger than concrete, and more durable than granite or marble. Its leach-resistance is among the highest of all materials in the world.

Through vitrification technologies, we offer an economical, practical way to protect the environment from the threats of nuclear and hazardous waste. GeoMelt® is ideal for solid waste and debris.

Industry Challenges

Despite glass’s superiority, conventional vitrification technologies have been too complicated – and far too expensive – to deploy widely. Such technologies also require a homogeneous waste feed and are less flexible than GeoMelt®.

Unlike most other vitrification technologies, GeoMelt® is cost effective and can process various types of wastes simultaneously.

GeoMelt® Technology Paradigm Change

How we transform waste into glass? GeoMelt® uses electric current to melt and produce glass. During the melt, hazardous wastes are destroyed from exposure to high temperatures, and radioactive isotopes are captured into a glass matrix. The GeoMelt® container is selected so that, after the melt, the glass within the container can be directly stored or disposed.

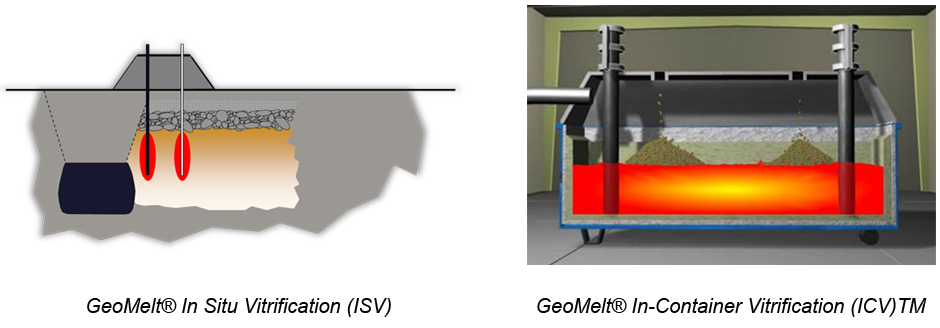

The GeoMelt® Systems can be an In-Situ vitrification technology ideal for soil, solid wastes and debris but also an In-Container vitrification technology ideal for waste streams. This is a unique commingling of wastes to utilize glass forming capabilities of one stream to stabilize the other.

GeoMelt’s® batch-treatment process delivers the following benefits that create its significant cost advantage:

Ability to customize the glass formulation and melting temperatures for a specific waste stream

Reduction of the amount of pretreatment

An increase in waste-loading capacity

The significant reduction of maintenance costs

A dramatic volume reduction

Minimizes handling of waste, thereby reducing risk to workers when compared to other waste treatment technologies

Through vitrification technologies, we offer an economical, practical way to protect the environment from the threats of nuclear and hazardous waste. GeoMelt® is ideal for solid waste and debris, while the Modular Vitrification System (MVS®) is designed for liquid waste.

Proven and Commercially Used Worldwide

GeoMelt® Melters have been treating nuclear and hazardous waste since the 1990s, producing over 26,000 metric tons of glass for disposal in the U.S., UK, Australia, Japan and other countries.

Initially developed by Pacific Northwest National Laboratory in the U.S., GeoMelt® has been used successfully around the world for the U.S. Department of Energy (DOE) in Hanford and at Sellafield in the UK for example.