The Story So Far

Since the 2011 disaster at the Fukushima Daichii Nuclear Power Plant, Veolia Nuclear Solutions has been a vital partner of the Japanese power utility TEPCO in the cleanup.

In the days following the March 2011 earthquake and Tsunami that damaged cooling systems on several reactors at the facility, TEPCO turned to Kurion, a company now owned by Veolia Nuclear Solutions, to help clean contaminated water.

Kurion’s initial objective was to create an external reactor water cooling system to remove the need to pour cooling water on the molten reactor cores via helicopters and pumper trucks, and to avoid further build-up of very high-activity cesium-contaminated wastewater collecting inside the basements of the buildings. The concern was that water would overflow onto the site grounds, rendering much of the site a high-dose hazard zone and pollute local fishing grounds.

In just eight weeks, Kurion designed, fabricated and delivered a 1,200 m3/day (317,000 gallons/day), first-of-a-kind external water-cooling system which featured the Veolia Ion Specific Media System (ISMS) to safely decontaminate the water.

Within the six months that followed, the ISMS had removed more than 70% of the cesium from the water. The plant was declared to be in a safe, secure, cold shutdown status. The ISMS was modified in 2015 to expand its decontamination capabilities, and continues to serve a mission-critical role today.

Removing Radioactive Strontium from Stored Water

In 2013, our Japanese partners turned to Veolia Nuclear Solutions once again to design and construct a system to remove radioactive strontium from the large amount of cesium-depleted water stored in the roughly 800 tanks then at the Fukushima Daiichi site. The goal was to improve the safety of the site by reducing radioactive dose and the risk to the surrounding environment should the tanks begin to leak. Veolia designed, fabricated, and delivered a 300 m3/day (80,000 gallons/day) first-of-a-kind at-tank Mobile Processing System (KMPS) to decontaminate radioactive strontium from the water on site. Composed of five modified ISO shipping containers, an innovative flow sheet and ion exchange media, the patented KMPS utilizes a modular, plug-and-process design for rapid deployment.

Veolia’s first KMPS started operating at Fukushima in early October 2014 and removed more than 99.95% of the strontium from the water. Veolia was then asked to build a second system identical to the first, which was delivered in just 13 weeks. The two KMPS treated and decontaminated 50,000 m3 (13 million gallons) of strontium-contaminated storage tank water, helping achieve a major milestone to improve safety at the Fukushima site by March 31, 2015.

Inspecting and Repairing The Damaged Reactors

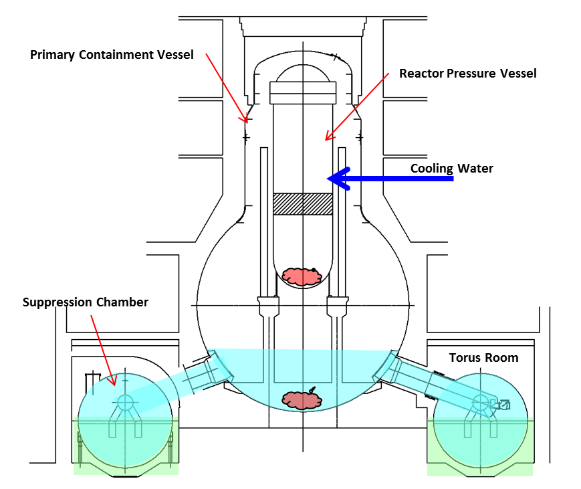

Although stabilized, the reactor buildings continued to require vast amounts of water to cool the fuel. To discontinue this process, TEPCO required a solution to inspect and fix leaks in the Reactor Pressure Vessel structure which would allow for the eventual retrieval of the fuel in future decommissioning activities. Veolia Nuclear Solutions led these efforts.

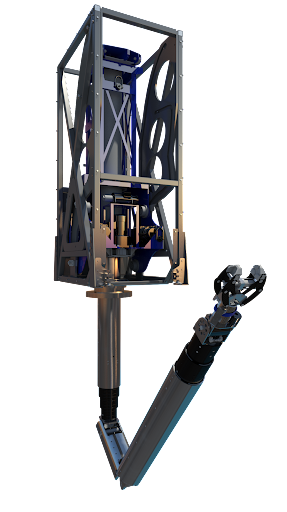

Veolia Nuclear Solutions was tasked to design, manufacture, test, and deliver two long reach robotic manipulator systems called the Fukushima Inspection Manipulator and Fukushima Repair Manipulator (FIM and FRM). The mission of these systems was to inspect and repair leaks in the lower levels of the Unit 2 reactor at Fukushima. The equipment was designed to be used in a very difficult operating environment which includes water, high radiation, contamination, and damaged infrastructure. These robots continue to operate and provide vital data, images and repairs.

Deploying PCVI Boom Technology

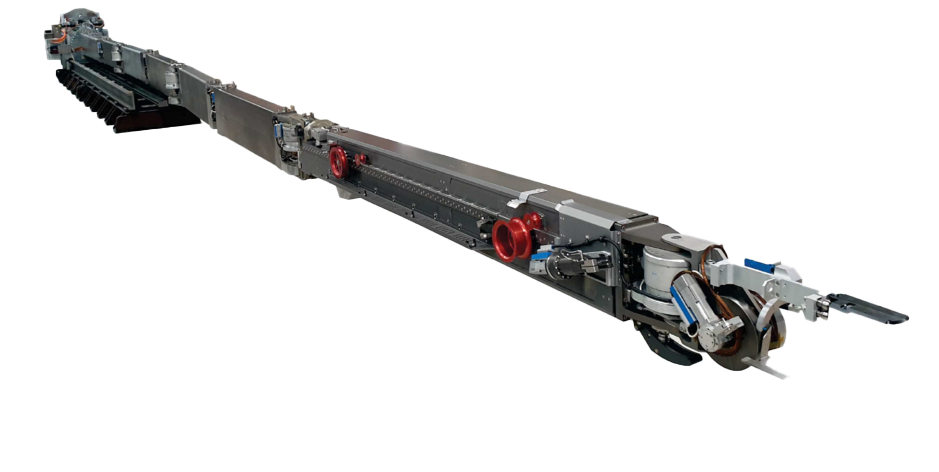

The next step in the decommissioning process involves removing fuel from the Unit 2 reactor. This presents a unique challenge given the highly radioactive environment, the distance the technology must travel to reach the reactor and a vast array of additional risk factors at play.

In July 2021 VNS along with our partners at Mitsubishi Heavy Industries, delivered to Japan a remotely operated articulated boom system. This world-leading technology is undergoing testing before it will be deployed in the Fukushima Daiichi nuclear facility to help with the ongoing restoration of the Fukushima Daiichi site where VNS’s Remote Access technologies will be used to inspect the Unit 2 reactor at the site. The long-armed boom will reach over 20 meters at full extension to help inspect fuel debris in the primary containment vessel and will provide critical information to support future work.

Conclusion

Throughout all of these efforts, Veolia Nuclear Solutions’ primary focus has been on supporting the Japanese authorities and our Japanese partners address the Fukushima recovery in the most safe, cost-effective and expeditious manner. Our experts from around the globe in France, the United Kingdom, Japan and the U.S. continue to collaborate with our Japanese partners, utilizing our collective experience to facilitate beneficial outcomes for the Fukushima project. Ultimately, the hope is that we can use our technology and expertise to allow the tens of thousands of people who have been displaced from their homes due to the disaster to one day return.