We assisted TEPCO in removing more than 370,000 trillion becquerel (10 million curies) of radioactive cesium from more than 370,000 m3 of contaminated water.

We also deployed a mobile technology platform to remove radioactive strontium from contaminated water. At the damaged reactors themselves, our Remote Access technologies will be used to first inspect and later to retrieve fuel debris.

Provide a cesium-removal system

At Fukushima, the chief concern was removing radioactive cesium from the millions of cubic meters of contaminated water. Cesium was the principal source of radioactive dose at the site and posed the greatest safety risk.

It was essential to capture the cesium so workers could more safely navigate the site and begin the cleanup.

Our solution was based on ion exchange between sodium and cesium, using our Ion Specific Media (ISM). Ion exchange materials can capture ions based on both their size and charge.

TEPCO needed media as well as a fully engineered system that it could put in place rapidly. We activated a supply chain to design and construct a cesium-adsorption system.

Results:

The 1,200 m3/day rated system was assembled and commissioned at Fukushima Daiichi site in thirteen days, followed by only one day of cold commissioning and three days of warm commissioning before hot startup with actual wastewater.

Our Ion Specific Media (ISM) has been used to remove more than 370,000 trillion becquerel (10 million curies) of radioactive cesium from more than 370,000 m3 of contaminated water

Our system contributed to TEPCO achieving the cold shutdown status on December 16, 2011 by delivering the following results:

Rapid eight-weeks for system design, fabrication, delivery and startup

Achieved cesium-removal goal of 99.9%

Responsible for more than 70% of radioactivity removed at the site

Processed more than 100,000 m3 of water

A Mobile Water Treatment System to Remove Strontium

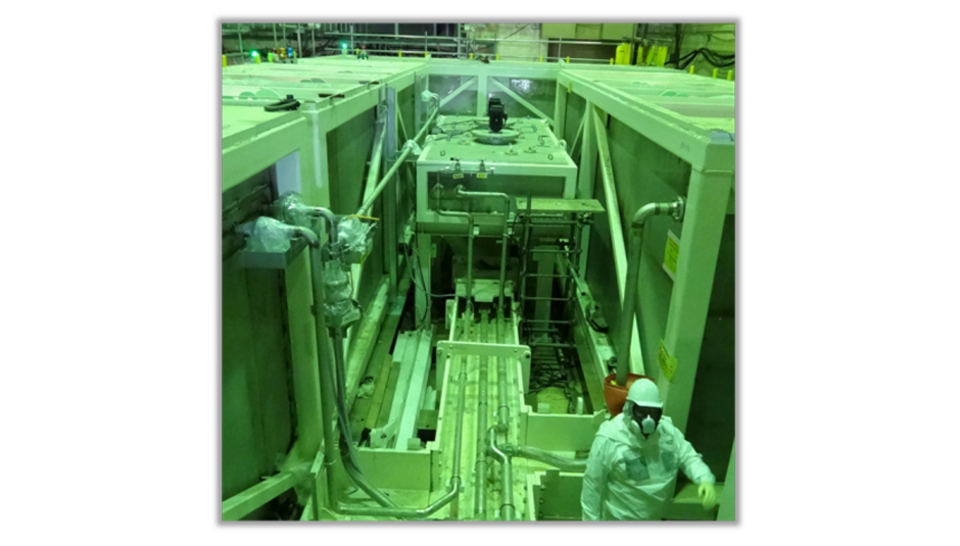

By 2014, TEPCO turned to us to design and construct a mobile system to remove radioactive strontium from the large amount of water stored in the tanks at Fukushima Daiichi site. To help improving the safety of the site and reducing the risk to the surrounding environment, we designed, constructed, and delivered a Mobile Processing System (KMPS). It was used for at-tank mobile water treatment system to remove radioactive strontium from the water.

How it works:

- KMPS is composed of five modified ISO shipping containers.

- It employs a modular, plug-and-process design, supplemented with additional filtration capabilities.

- KMPS was designed, constructed and delivered in seven months, and has a process rating of 300 m3/day.

Results:

Our first KMPS started operating at the Fukushima Daiichi site in early October 2014 and removed more than 99.95% of the strontium from the water

When fabrication of the first system was nearly complete, TEPCO asked us to build a second system identical to the first, which was delivered in only 13-weeks and went into operation in February 2015.

The two KMPS contributed to TEPCO reaching an important safety milestone in the cleanup in May 2015 by removing strontium from the water.

Since then, Veolia Nuclear Solutions continue l working in close collaboration with TEPCO and Japanese nuclear industry to support remediation efforts at Fukushima Daiichi Nuclear Power Plant, in a safe and cost effective way.