Newport News Shipbuilding (NNS), a Division of Huntington Ingalls Industries, designs, builds, refuels, and overhauls US Navy aircraft carriers. As a part of a routine overhaul, radioactively contaminated tanks are refurbished prior to redeployment.

Tank refurbishment includes multiple iterations of decontamination, paint blasting, repair, recoating, and inspections of the interior surfaces. Currently, this process is accomplished by shipyard personnel that enter the tank and manually perform each of the tasks. Radiological exposure and confined space are among many hazards workers face while performing this task. NNS is seeking methods to decrease the time, cost, and risks associated with refurbishing these tanks.

To assist with this task, Veolia Nuclear Solutions has developed a remote Tank Refurbishment System (TRS). The TRS consists of the Tank Refurbishment Manipulator (TRM), Deployment/Retrieval Tool (DRT), a tool kit, and the remote control console.

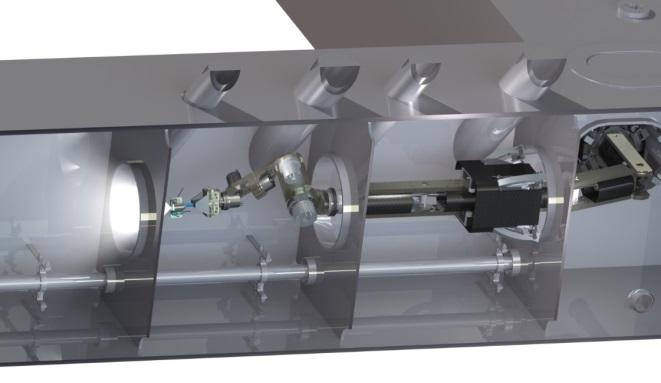

The TRM will access the tank through circular openings cut through the ships hull (Figure 1) using separate cutting equipment.

Figure 1 - Entrance into the Tank

Once inside, the TRM will move "inch-worm-style" through the tank bays (Figure 2), stopping as required to perform the required task(s).

Figure 2 - Movement through the Tank (1 Bay)

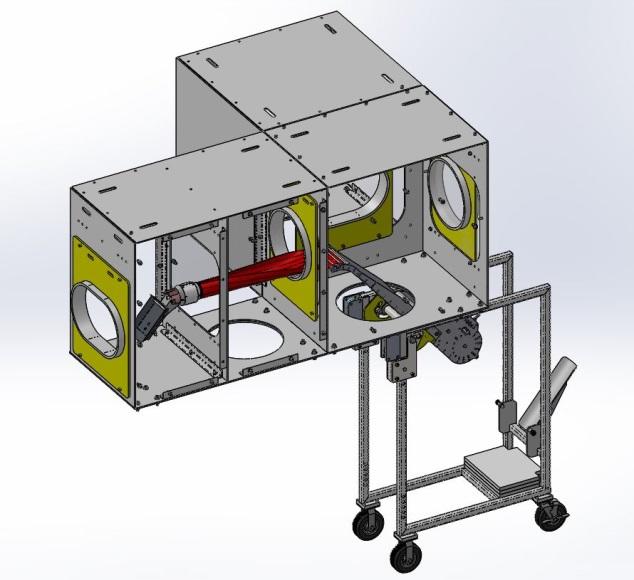

The DRT is deployed through another opening in the bottom of the ship. It supports the TRM by providing and removing the tools and materials required for the refurbishment process (Figure 3).

Figure 3 - Deployment/Retrieval Tool Positioned in Tank

The DRT provides the tools deployed by the TRM to perform the various tasks required to refurbish the tank. The tools decontaminate surfaces inside the tank, protect tank internals, remove/apply paint, and manipulate tank internal components.

The remote control station is located outside of the tank in a remote area. Operators will control movement and operation of the equipment from the remote control station.

> To know more about the Remote Access Solutions