Mock-ups Today

Today, the integration of modern CAD, BIM and other systems with physical mock-ups continues to play a crucial role in major projects worldwide, including across the NDA fleet, EDF’s CHINON A2 in France and Fukushima in Japan.

A significant advancement involves the fusion of physical mock-ups with cutting-edge technology such as virtual reality, digital twins and interacting with operational sequence descriptions. These can all be used at every stage of the design process , during testing in a full-scale mock-up and continue to be used in operations so operators have use of camera views as well as full VR positioning within the operating environment.

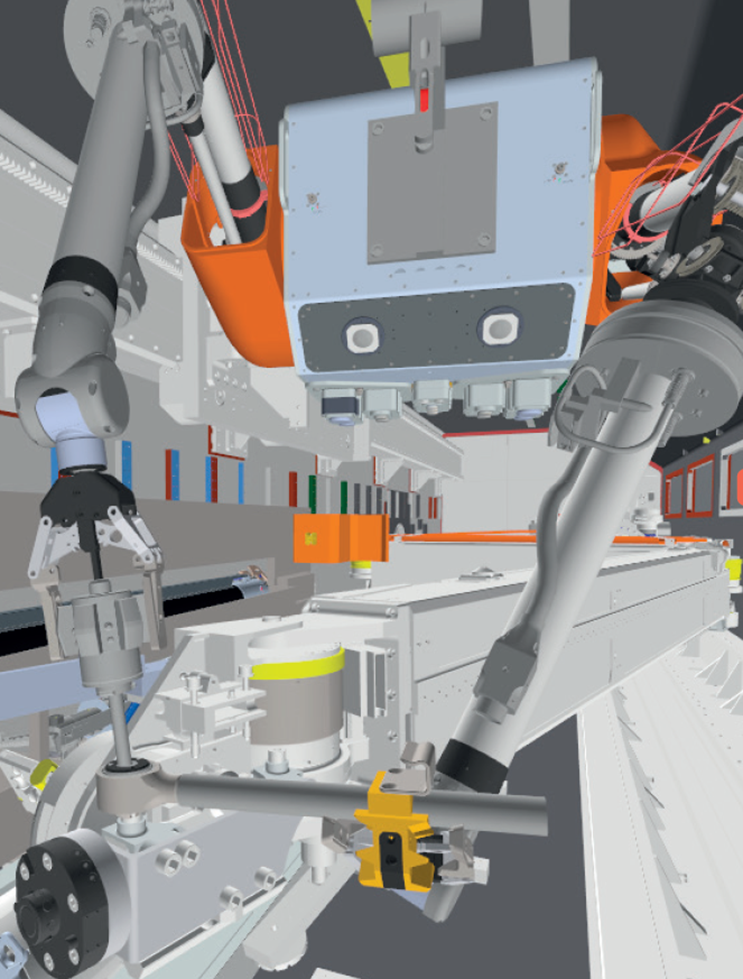

One such system perhaps better identified as using ‘real time simulation technology’ has been pioneered by Dutch company Tree C Technology, which delivers interactive visualisation of designs and ideas in the early phases of a project supporting equipment design, task development, training of operators and – eventually – the operation.

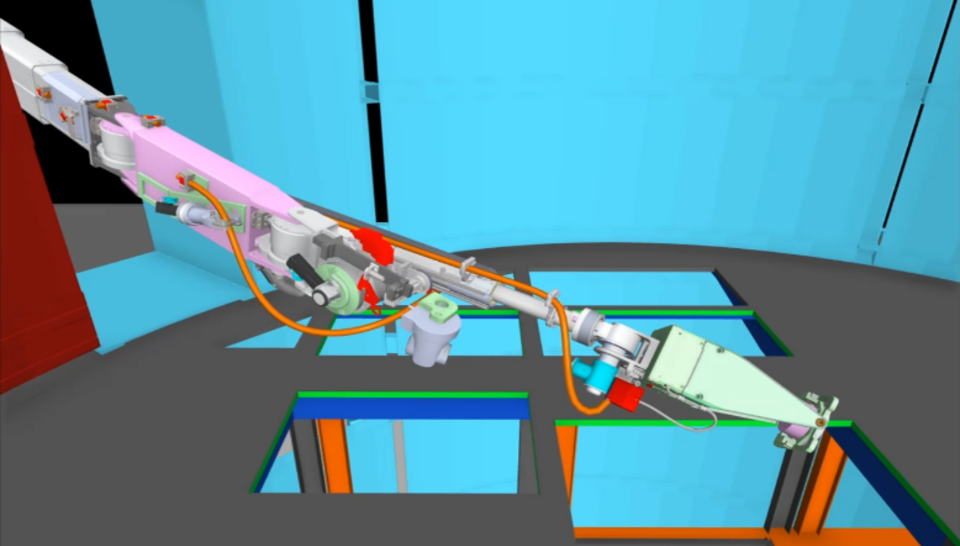

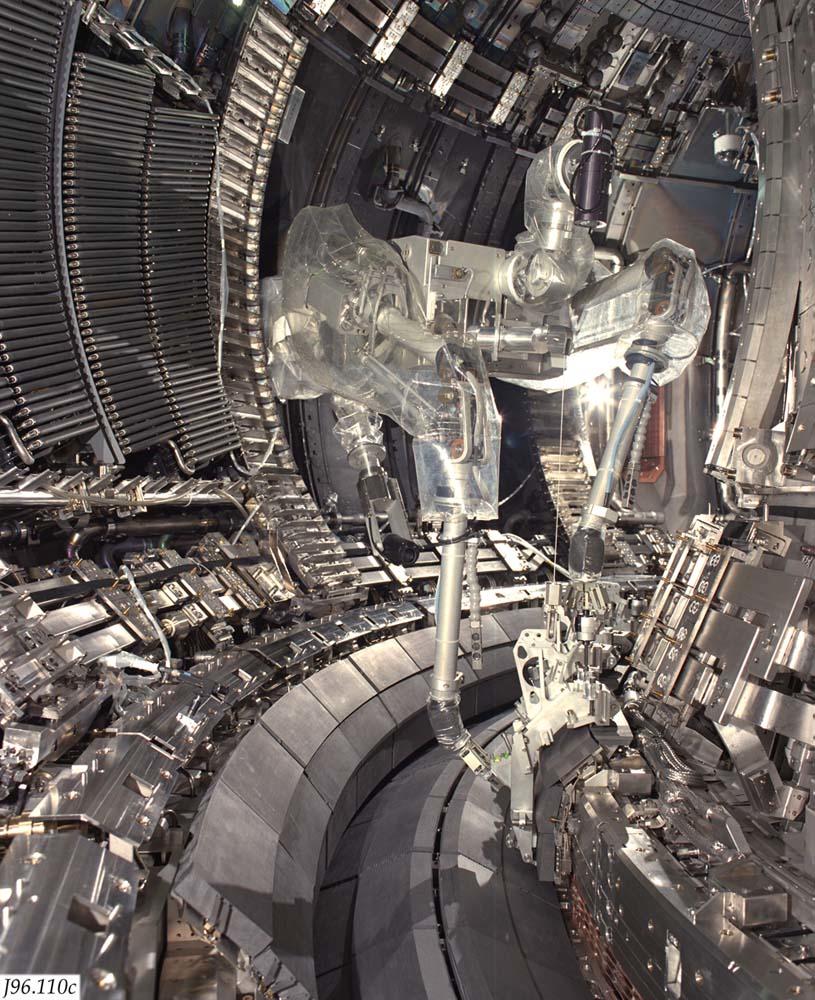

The Tree C system was enhanced by VNS UK to optimise it specifically for use with robotic machinery. This ‘integrated design, testing, training & operating real time simulation technology’ proved highly effective during the maintenance and upgrade programme of the JET Fusion Reactor in the early 2000’s. It facilitated the remote entry of a multi-armed boom and a dexterous, two-armed manipulator called ‘mascot’ into the reactor, eliminating the need for human entry into this hazardous environment. The system was instrumental in developing protocols, sequencing, and operator training within a large-scale mock-up, providing real-time positional awareness and feedback, especially in environments with limited visibility.

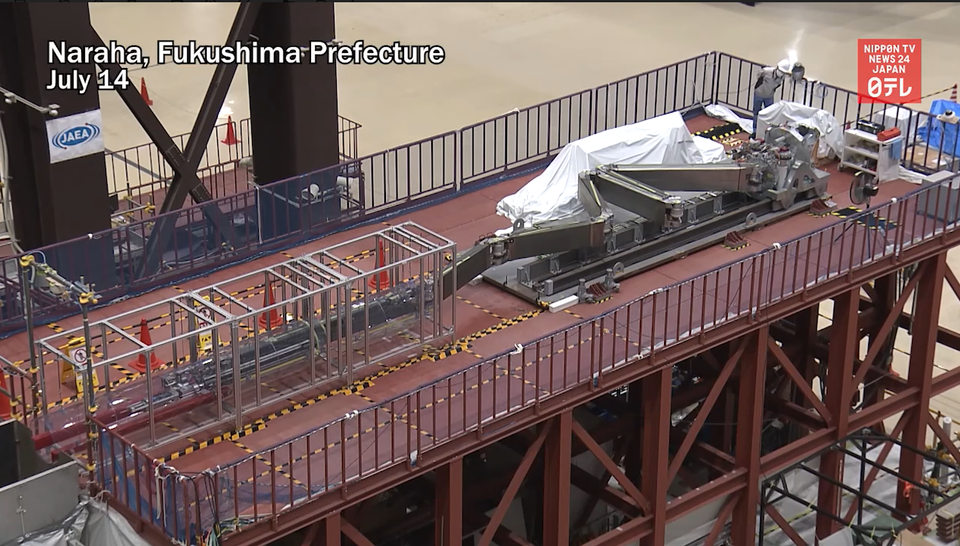

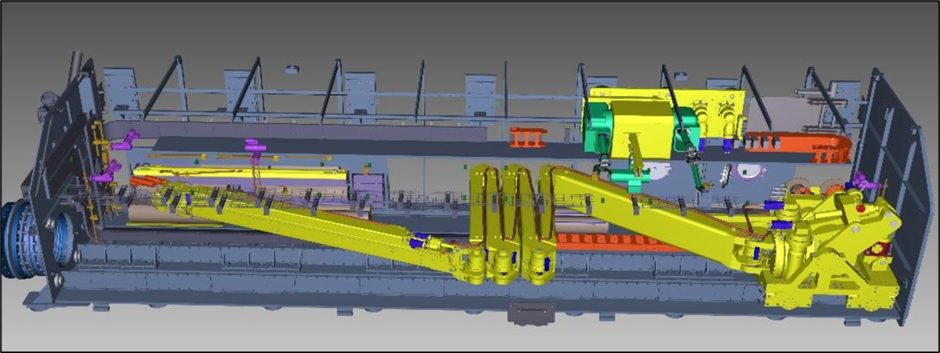

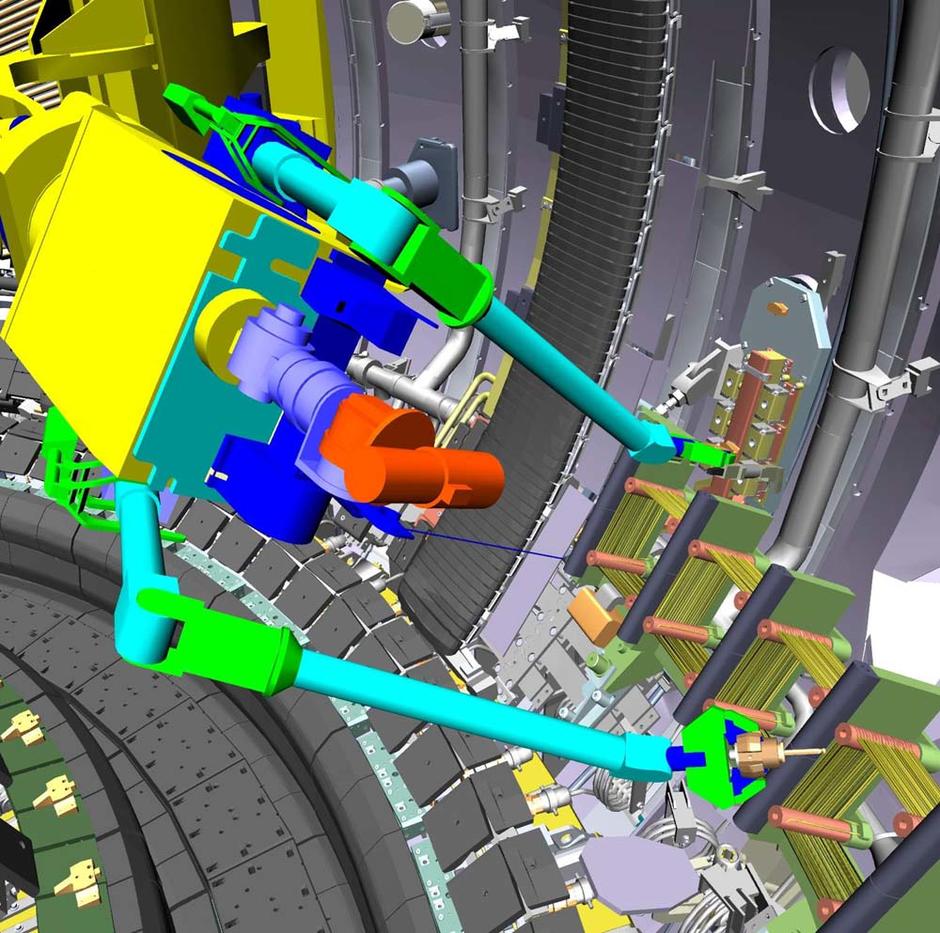

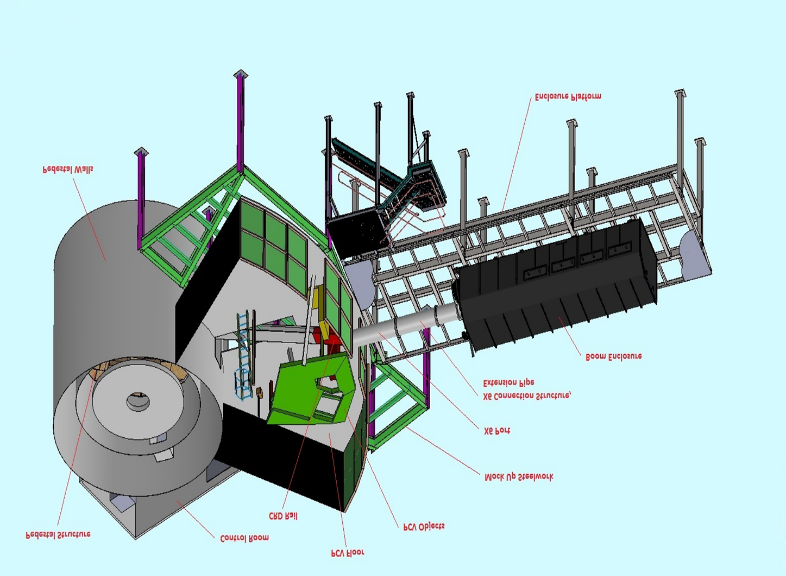

Today Tree C Technology, in partnership with Veolia Nuclear Solutions UK, has continued to advance their approach for various projects, including ITER and the decommissioning of Daiichi Fukushima reactor’s Unit 2. They have extensively employed real-time simulation and digital mock-up testing in the design and development of remote handling systems. Real time simulation and digital mock-up testing has been used throughout the design, including in full mock-ups in the assembly facility in the UK and currently at the Naraha testing facility adjacent to the Fukushima site.

This approach has proved invaluable, not only in designing and validating the systems but also in demonstrating operational effectiveness, operator training, and spatial awareness assessment for the 21 metre boom system within the damaged environment.

The same approach has been embraced by the Graphitech JV (a partnership between EDF and Veolia) for the CHINON A2 UNGG reactor decommissioning project. The author believes that this technology is poised to become the standard approach for complex decommissioning projects in the future.

Examples showcasing the integration of real time simulation with physical and digital mock-ups are provided below:

ABOUT THE AUTHOR

With nearly 40 years of experience in the nuclear industry, David Loughborough has made significant contributions to various aspects of the field. His journey began in 1985 as a graduate at AERE Harwell, following an apprenticeship and earning a degree. In the 1980s, he worked on the circular filter development program, and during this time, he built his first mock-up of an MOD facility to demonstrate an accident scenario safety feature.

Throughout the 1990s, David managed projects at Harwell, Amersham International, and AWE. His expertise expanded to include leading teams at Dounreay, focusing on design, reactor maintenance, and decommissioning. He then went on to work for renowned organisations such as Jacobs, AREVA (now ORANO), and Veolia, where he served as the Managing Director of VNS UK, the UK Nuclear arm of Veolia.

David's contributions extend beyond his project management roles. He has actively participated in British and European standards committees for nuclear ventilation and filtration. He has also published papers on his decommissioning projects and has shared insights on training and developing project managers. In recognition of his exceptional work, he was awarded the APM's PM of the Year in 1995.

Most recently, David has developed a comprehensive training program aimed at supporting non-nuclear engineers, designers, and project managers as they transition into the nuclear industry. This program provides a thorough introduction to the nuclear industry's history and current practices, equipping professionals with the knowledge and skills required to excel in their roles.