Modern Day Mock-ups

While modern design processes have seen extensive use of CAD systems, BIM (Building Information Modelling) and advanced visualisation tools such as 2D and 3D walk-throughs, it doesn’t necessarily follow that the days of mock-ups are numbered.

The value of a mock-up depends on the specific context and benefits they offer, as outlined in the previous examples. To reiterate:

1.Tangible Validation: Mock-ups provide a physical representation that can validate design concepts and operational procedures in a real-world context. This is especially valuable for complex or high-stakes projects.

2. Operational Realism: They allow for the testing of operational scenarios that may be difficult to simulate entirely in virtual environments, ensuring that real world challenges can be addressed.

3. Human Interaction: Mock-ups offer a hands-on experience, allowing operators and project stakeholders to physically interact with the design, which can be important for training and understanding and increasing operational efficiency.

4. Safety Assurance: In hazardous or critical environments, physical mock-ups can serve as a crucial tool for safety validation, ensuring that protocols and procedures are effective.

5. Client and Regulator Confidence: All of the work during the mock-up period helps to increase Client and Regulator confidence that the proposed solution will work.

Today, there are many examples of large-scale mock-ups benefitting a project. For example, a well known project demonstrating this is the Dounreay Shaft project - one of the UK’s most complex challenges.

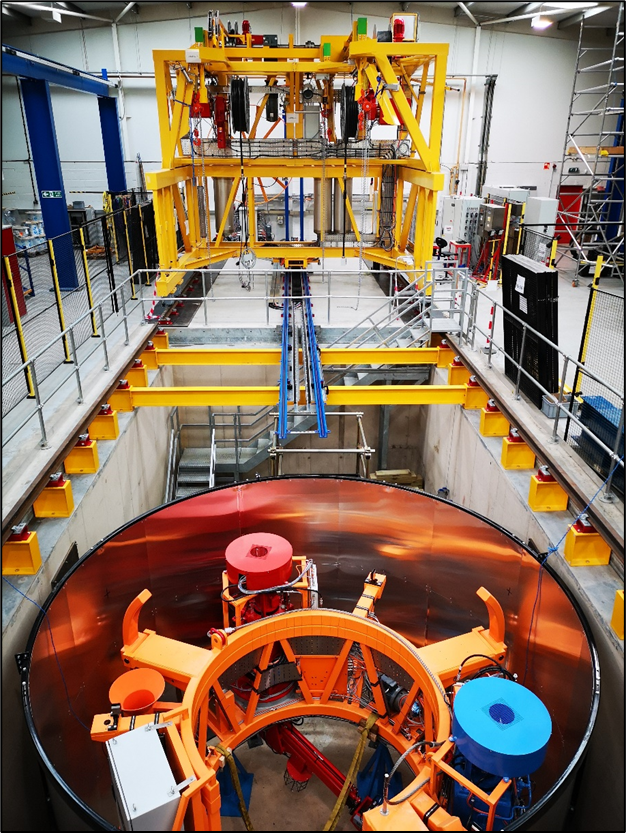

A view of the Shaft Intervention Platform (SIP) (yellow structure) that moves over the shaft two manipulators supported on a lifting frame (orange structure) and works interactively with a grab mechanism to remove the waste. Top 5m of the shaft was built in the VNS facility in Abingdon as part of long-term trials.

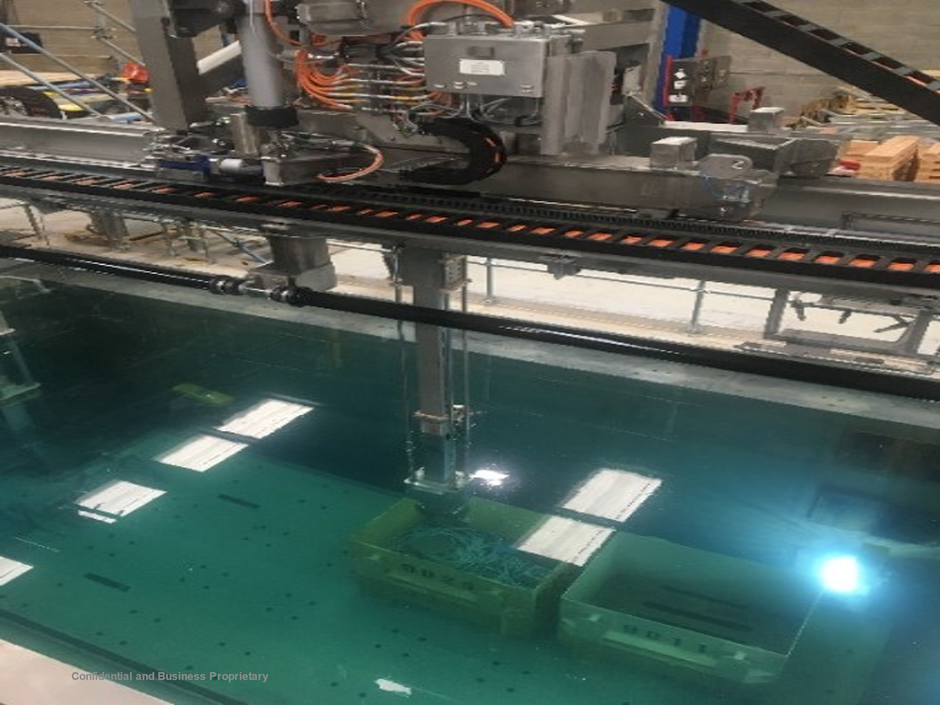

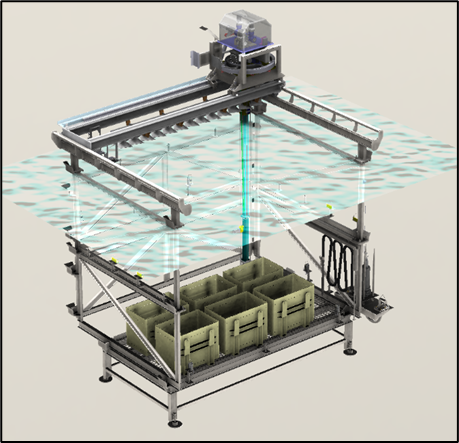

Another recent example is the ground-breaking mock-up used to validate the installation, maintenance and operation of a remote handling structure in one of the world’s most hazardous storage ponds, located at the Sellafield facility in Cumbria. Now installed in the pond it marks the beginning of a 20+ year programme aimed at sorting, segregating and transferring materials contained within hundreds of metal baskets. (image to the right)

This shows the structure being tested in 5 metres of water. Critical aspects of rapid assembly (taking into consideration radiation levels at the operating location and 3 modular sections to suit the site cranage limits, maintenance capabilities and a wide range of operations were evaluated in this unique underwater facility.

ABOUT THE AUTHOR

With nearly 40 years of experience in the nuclear industry, David Loughborough has made significant contributions to various aspects of the field. His journey began in 1985 as a graduate at AERE Harwell, following an apprenticeship and earning a degree. In the 1980s, he worked on the circular filter development program, and during this time, he built his first mock-up of an MOD facility to demonstrate an accident scenario safety feature.

Throughout the 1990s, David managed projects at Harwell, Amersham International, and AWE. His expertise expanded to include leading teams at Dounreay, focusing on design, reactor maintenance, and decommissioning. He then went on to work for renowned organisations such as Jacobs, AREVA (now ORANO), and Veolia, where he served as the Managing Director of VNS UK, the UK Nuclear arm of Veolia.

David's contributions extend beyond his project management roles. He has actively participated in British and European standards committees for nuclear ventilation and filtration. He has also published papers on his decommissioning projects and has shared insights on training and developing project managers. In recognition of his exceptional work, he was awarded the APM's PM of the Year in 1995.

Most recently, David has developed a comprehensive training program aimed at supporting non-nuclear engineers, designers, and project managers as they transition into the nuclear industry. This program provides a thorough introduction to the nuclear industry's history and current practices, equipping professionals with the knowledge and skills required to excel in their roles.