Evolving technology and how it is driving change across the hazardous waste sector: Simon Delavalle, Chief Technology Officer for Veolia Nuclear Solutions UK tackles this topic in this month's edition of Nuclear Engineering International magazine.

Innovative Technology

Innovative technology is continuing tochange how we live our lives. From people accessing their smart phones an average of 150 times a day to order groceries and control their finances, to advances in augmented reality and the metaverse, technology is redefining our lives and jobs every day. The hazardous waste industry is no different, and rapid advances in technology and innovative new solutions are reshaping how firms and their service providers are thinking about even the most complex nuclear waste challenges they face. Increasingly, the question is not if technology should be deployed in a specific circumstance; rather, it’s how can the latest technology be utilised to increase efficiency, reduce the lifetime costs associated with addressing a particular waste challenge, and increase worker safety?

The ongoing cleanup of the Fukushima Daiichi Nuclear Power Plant

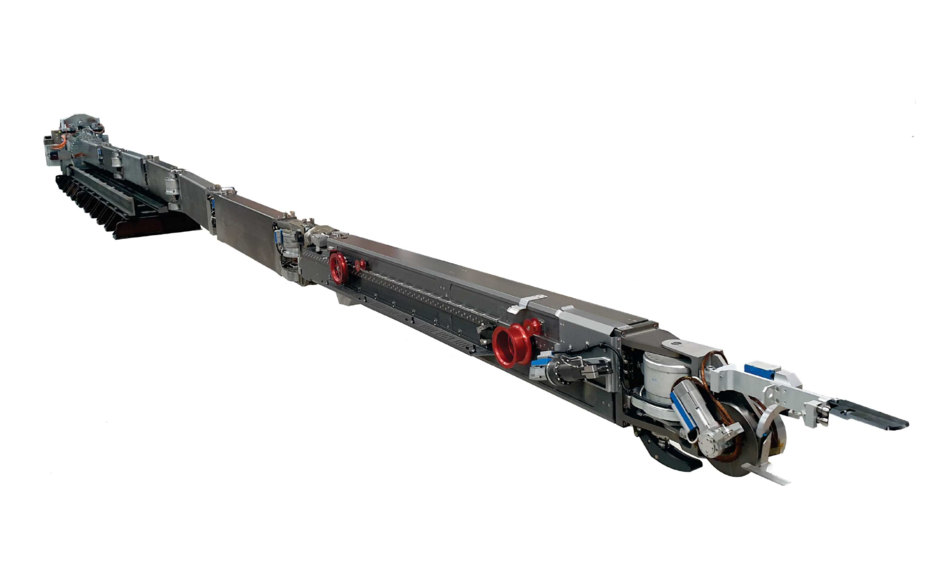

The site is a great example of how constantly evolving technology is driving significant change in the way operators are thinking about significant hazardous waste projects. Specifically, an ongoing challenge has been to investigate the Primary Containment Vessel at Fukushima reactor number 2 so that damaged fuel and other debris can eventually be removed. The challenges are immense: the environment is highly contaminated, doesn’t permit human access, and is hard to navigate. To tackle this challenge Veolia Nuclear Solutions called on its technology expertise to design a unique and complex robotic system that could be stored in a restrictive volume, deployed through a long and narrow aperture and navigate the unknown obstructed environment of the stricken nuclear reactor.

Robotic Design

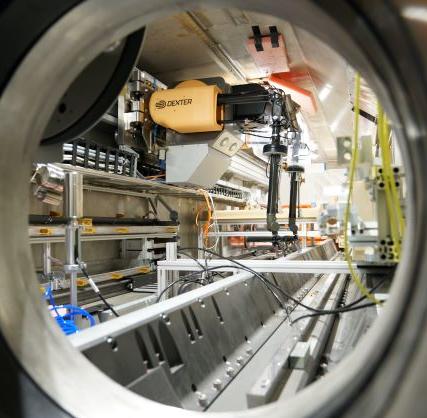

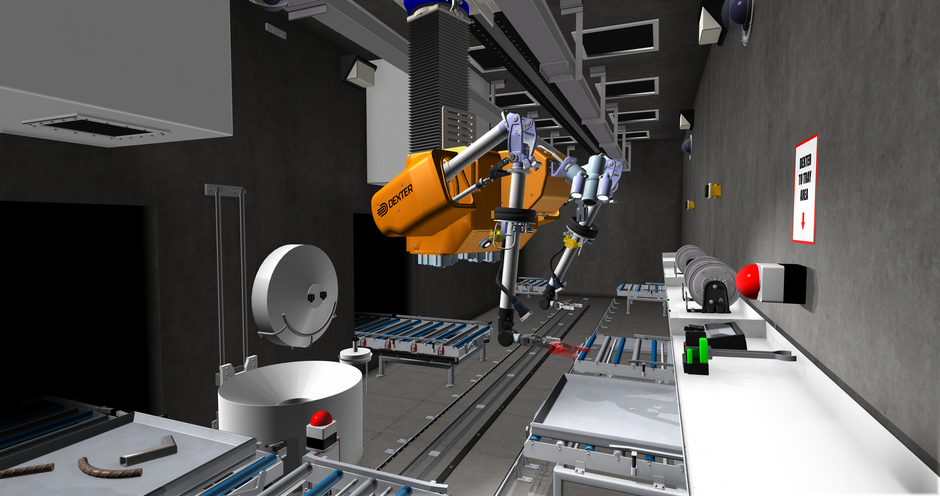

Designing the robot was just one part of the complex problem they faced. Even in a test situation, such a system can be difficult to operate, let alone in a damaged nuclear reactor. That’s why VNS also included the Retiina™ digital solution, which includes VNS proprietary control software and interface as well as Tree C Technology VR4Robots® digital twin, to operate the robotic system in a planned, controlled and intuitive manner. This digital tool suite enabled VNS not only to plan and record operations before the machine was complete, but also to train the future operators in the exact details of the operating environment they would face at Fukushima. The addition of VNS’s Dexter™system, a force feedback manipulator, allows intuitive operations of all the configuration, import and maintenance tasks required, enabling operators to focus on the task to be accomplished rather than operating a machine. By analysing the challenges faced and understanding which tasks require human capabilities, and which benefit from technological augmentation, VNS was able to create a system tailored specifically to the problem at hand.

The result?

A unique pairing of human and machine teaming that harnesses the rapid advances in robotic control and digital twin technologies to allow experienced hazardous waste practitioners to successfully do their jobs more efficiently and safely. That’s not the only area where technology is simplifying the solutions to complex problems. The long-term stabilization and disposition of hazardous waste has been an evergreen challenge for the nuclear waste industry for decades, but technology – specifically vitrification technologies – is allowing operators to rethink how they can approach site remediation and waste disposal.

Simon Delavalle, Chief Technical Officer,

Veolia Nuclear Solutions, UK

Above: Dexter™ in the robotic boom enclosure

Above: Dexter’s digital twin in the Retiina system

GeoMelt® Technology

Veolia Nuclear Solutions’ GeoMelt® technology has forged a pathway for this new approach. Commercially proven and allowing for the simultaneous processing of a range of radioactive, inorganic and organic waste, and reactive metals, GeoMelt provides scalability, flexibility and scalability, reducing life-cycle costs and reducing worker risk by minimizing handling of waste. Technology can help make the complex simple. In the nuclear waste industry, that increasingly means designing and implementing technologies to improve project efficiencies, keep workers out of harm’s way, and create improved pathways to success. VNS continuously studies the application and integration of emerging technologies toward this vision.

Innovate UK Grant

One of the latest steps is the integration of quickly expanding AI technologies to new systems in innovative ways. For example, VNS has been awarded a Innovate UK grant to develop a first prototype of a human-machine teaming system for nuclear waste sorting, using AI for automation of the bulk of the task and leveraging the unmatched human skills and decision making when required for the most difficult and critical tasks. VNS will be exploring these topics and how to harness technology when approaching the most complex hazardous waste challenges in an upcoming webinar.