For RXT, the value proposition is to tackle a simple challenge: the oil and gas transportation and storage infrastructure industry has hundreds of thousands of tanks, containers and other vessels that need to be cleaned regularly each year. Unfortunately, there has been no significant advancement in cleaning and maintenance technologies for decades. Whether it is natural gas pipelines and storage tanks, crude oil storage infrastructure, or ocean-going tankers and processing infrastructure, all of these containers need to be regularly cleaned. Unfortunately, this type of cleaning is extremely dangerous and time consuming; typically, a person must enter a hazardous confined tank and then clean it manually with a high-pressure device. The reality is that these operations can create unnecessary risks while also reducing operational efficiency.

Through RXT, Veolia Nuclear Solutions is breaking the mold and laying the groundwork for an enormous opportunity: utilizing its best-in-class remote-access technologies to revolutionize this critical business process for the transportation and storage infrastructure cleaning and recoating industries.

Additionally, it is an opportunity with the important goal of never again putting workers at risk inside a tank or container. No longer will workers have to fit themselves into dangerous, confined spaces where they have to inhale or expose themselves to harsh chemicals in order to clean a tank. With RXT, risk reduction and worker safety are paramount, while also increasing cleaning efficiency, effectiveness and reducing operational costs.

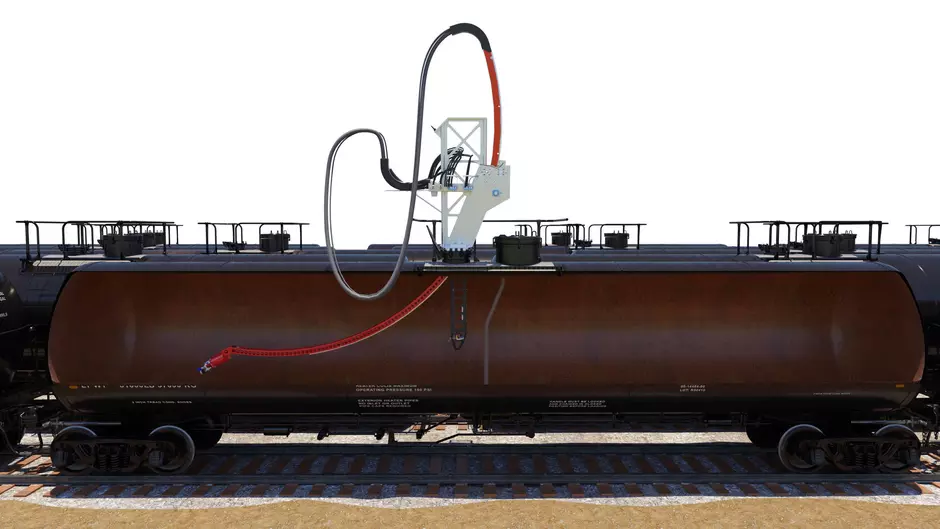

The new RXT business will bring to market a range of products and capabilities, pairing VNS’ world-class expertise with other field-proven technologies that have made Veolia a trusted partner around the globe. This technology includes VNS’ experience helping respond to the Fukushima nuclear disaster - arguably the most challenging remote confined space project ever encountered. The RXT business includes FRACCESS, for cleaning frac tanks; T-Trax for train tankers; S-TRAX for semi-tankers; H-TRAX and V-TRAX for horizontal and vertical stationary product tanks; and M-TRAX for marine tankers and similar water-bound vessels.

The market for these products is significant: conservative industry estimates suggest that the initial market for FRACCESS and T-TRAX is roughly 400,000 tanks already in service. Those tanks require an enormous 1.2 million cleaning evolutions per year!

The RXT team is moving ahead aggressively to make this new business a success. The first T-TRAX units will be available for lease in the first half of 2019, and already has excited customers ready to lease the new technologies.

It’s fair to say, RXT is ready to “clean up” in the tank-cleaning business.