The nuclear industry, a cornerstone of low-carbon energy generation, faces an enduring challenge: the safe, efficient, and cost-effective management of its radioactive waste. For decades, the approach to sorting and segregating this complex waste stream has relied heavily on manual methods. While born of necessity, these traditional techniques are increasingly revealing their limitations. Mounting decommissioning liabilities, stringent regulatory demands, and the sheer diversity of legacy waste forms are exposing fundamental inefficiencies.

Reliance on human operators, often working in demanding conditions via remote handling or suited entry, inherently carries risks. Radiation exposure, potential contamination, and the physical strain of repetitive tasks are constant concerns. Beyond safety, manual sorting is often slow, susceptible to human error in characterisation and segregation, and struggles to achieve the packing efficiencies needed to optimise costly final disposal routes. Furthermore, many sites grapple with legacy wastes – drums, boxes, and bags filled decades ago, often with incomplete or unreliable documentation, presenting significant unknowns.

The industry requires solutions that move beyond incremental improvements to fundamentally transform how we approach waste management. That transformation is arriving in the form of intelligent automation.

Simon Delavalle, Chief Technical Officer, Veolia Nuclear Solutions

The Rise of Intelligent Automation in Hazardous Environments

Automation is not new, but the integration of artificial intelligence (AI), advanced robotics, and sophisticated sensing technologies marks a significant leap forward, particularly for hazardous environments. Where simple automation might replicate a repetitive task, intelligent automation introduces capabilities for perception, decision-making, and adaptation that are crucial for the unpredictable nature of nuclear waste.

This isn't merely about replacing human hands with robotic arms; it's about augmenting human capabilities and overcoming the inherent limitations of manual processing. Intelligent systems can perceive and interpret data from multiple sensors simultaneously, make complex sorting decisions based on pre-defined criteria and learned patterns, and execute precise handling tasks tirelessly and consistently.

From Concept to Proven Capability: The BI-SENSS Example

Moving intelligent automation from laboratory concepts to deployable industrial solutions requires significant research, development, and rigorous testing. Veolia Nuclear Solutions, through initiatives like the InnovateUK-backed BI-SENSS (Blended Intelligence for Safe and Efficient Nuclear Sort and Segregation) project, has been at the forefront of demonstrating the tangible benefits of this approach.

This project, and the subsequent development efforts it spurred, tackled the core challenges head-on:

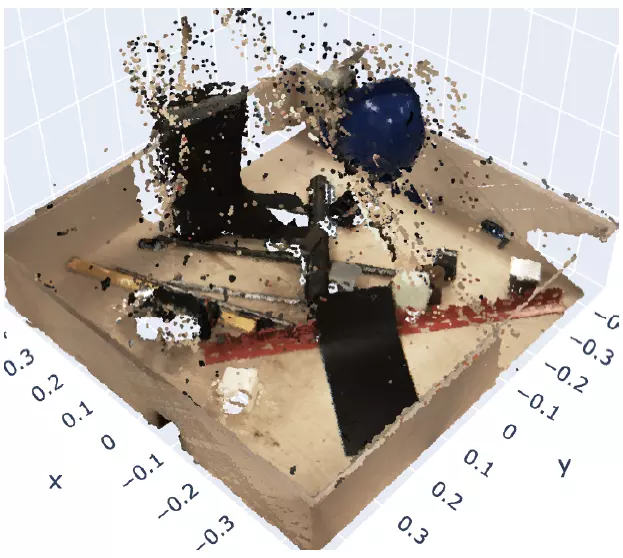

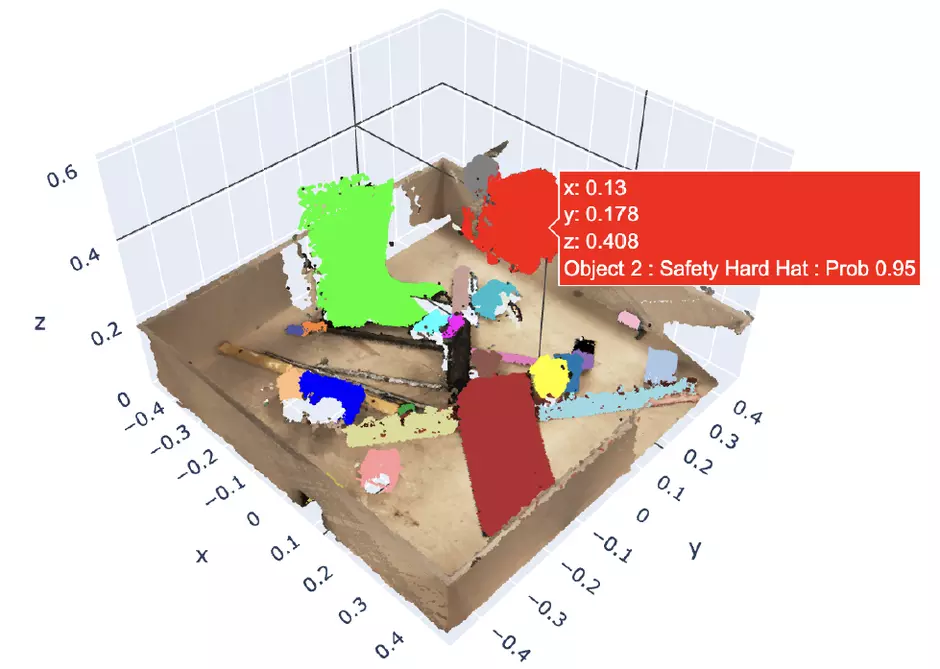

Advanced Waste Identification & Characterisation: Traditional manifests are often insufficient. Intelligent systems leverage machine vision coupled with AI algorithms to visually identify items. Crucially, this is fused with data from other sensors, such as gamma spectroscopy for radiological fingerprinting or X-Ray Fluorescence (XRF) for material composition analysis. This multi-modal sensing provides a far richer, real-time understanding of each waste item, enabling accurate segregation based on material type, radiological profile, and destined disposal route.

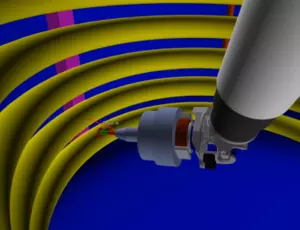

Autonomous Handling of Diverse Forms: Nuclear waste doesn't come in uniform packages. Systems must grapple with drums, boxes, trays, big bags, and even loose piles of debris. Advanced robotic manipulators, like VNS’s DEXTER™ haptic telemanipulator – already proven in high-radiation environments – equipped with versatile end-effectors and autonomous motion planning, can carefully grasp, manipulate, and place items with precision far exceeding manual remote handling, even performing complex tasks like autonomous drum opening.

Robustness and Edge Case Management: Real-world waste streams are inherently variable. A purely autonomous system might struggle with highly unusual items or unforeseen situations. Mature solutions, therefore, adopt a hybrid approach. While automation handles the vast majority of tasks efficiently, the system retains the capability for skilled human operators to intervene via intuitive teleoperation when necessary. This 'human-in-the-loop' philosophy, combined with robust fail-safes and real-time monitoring, ensures operational continuity and safety even when encountering the unexpected.

Optimised Packing for Disposal Efficiency: Sorting is only part of the equation. How waste is packed into disposal containers significantly impacts costs, particularly for intermediate-level waste (ILW) destined for geological disposal facilities where space is at a premium. AI-driven algorithms can analyze the geometry and characteristics of sorted waste items to calculate optimal packing arrangements, maximising container utilisation. Projects like BI-SENSS demonstrated potential packing efficiency improvements of up to 60% compared to manual approaches – a figure that translates into substantial cost savings over the lifetime of a decommissioning project.

Data Integrity and Digital Traceability: Intelligent automation inherently generates vast amounts of data about each waste item – its identity, characteristics, radiological signature, and handling history. This creates an unprecedented opportunity for robust digital record-keeping. Comprehensive, accurate data enhances traceability, simplifies compliance reporting, aids long-term waste management planning, and provides valuable input for managing downstream processes and final disposal tenders.

Tailored Approaches for Different Waste Types: Recognising that not all waste is the same, development has focused on differentiating requirements. For instance, managing alpha-contaminated waste presents different detection challenges, containment requirements, and handling risks compared to beta/gamma waste. Intelligent systems can be configured with the appropriate sensors, shielding, and handling protocols specific to the waste stream being processed.

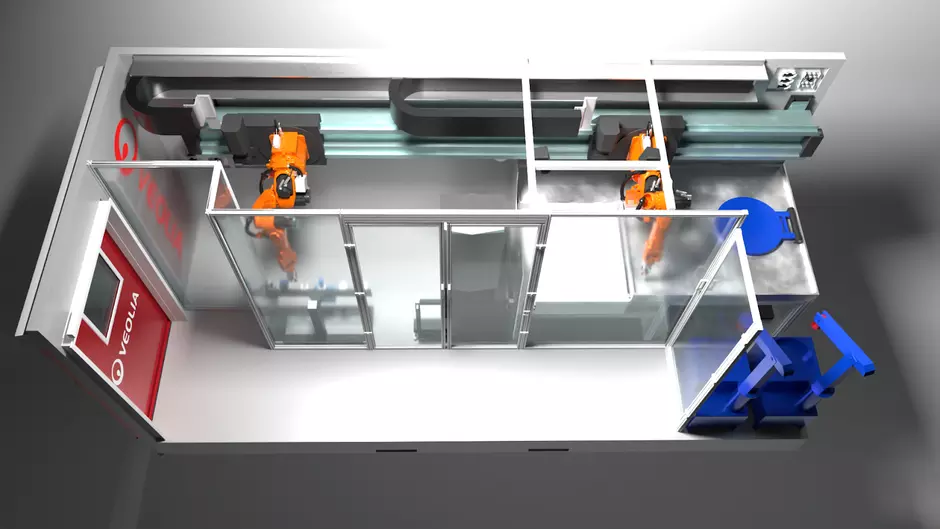

Deployable, Modular Systems: Bringing the Solution to the Site

The transition from R&D success to industrial application hinges on deployability. VNS is developing modular autonomous sorting systems designed for rapid deployment and adaptability. Pre-engineered modules reduce on-site setup time and complexity. This modularity allows systems to be scaled according to throughput needs and reconfigured to handle different waste campaigns or container types. Containerised solutions, such as the BI-SENSS Drum Sorting System (B-DSS), offer a self-contained processing capability that can be delivered directly to a site, either for purchase or 'as a service', providing operational flexibility and reducing the upfront capital investment burden for site operators.

The Tangible Benefits: A Fundamental Change in Practice

The adoption of intelligent automation in waste sorting is not merely a technological advancement; it represents a fundamental shift in operational philosophy with tangible benefits for nuclear site owners and operators:

- Enhanced Safety: Dramatically reducing human intervention in hazardous zones directly supports ALARA principles and minimises personnel risk.

- Increased Efficiency & Throughput: Automated systems operate faster and longer than manual methods, accelerating decommissioning timelines and processing campaigns.

- Improved Accuracy & Compliance: AI-driven characterisation and sorting minimise errors, ensuring waste meets acceptance criteria and enhancing data quality for regulatory bodies.

- Significant Cost Savings: Reduced labour requirements, optimised waste packing leading to lower disposal volumes, and increased operational speed contribute to substantial overall cost reductions.

- Operational Flexibility: Modular and deployable systems adapt to changing site needs and diverse waste streams.

- De-risking Operations: Leveraging proven, mature technology backed by extensive R&D minimises implementation risks and ensures reliable performance.

Conclusion: Embracing the Automated Future

The challenges of nuclear waste management are complex and demand innovative solutions. While manual methods have served the industry, the limitations are clear. Intelligent automation, integrating AI, robotics, and advanced sensing, offers a proven path forward. It moves beyond conceptual ideas to deliver deployable, modular systems capable of tackling the intricacies of waste identification, handling diverse forms, ensuring robustness, and optimising packing.

Through sustained investment, Veolia Nuclear Solutions is demonstrating that these technologies are no longer conceptual; they are mature, field-ready, and solving real-world problems. By embracing intelligent automation, the nuclear industry can enhance safety, boost efficiency, improve compliance, and achieve significant cost savings in its waste management and decommissioning programs. This is not just about adopting new tools; it's about strategically positioning the industry for a safer, more sustainable, and economically viable future in managing its radioactive legacy.

Contact Veolia Nuclear Solutions today to learn how intelligent automation can optimise your nuclear waste management.