A touch-sensitive remote manipulator system

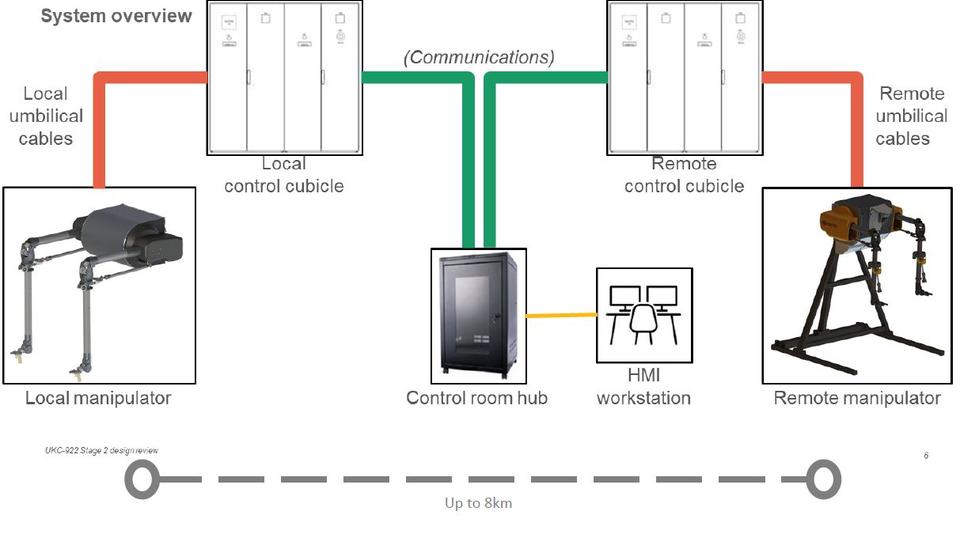

The human operator performs tasks with the local manipulator, which the remote manipulator replicates exactly, in real time, in the remote location. The remote manipulator can be positioned up to 8km from the local manipulator because there’s no mechanical connection between the two - just cables for data.

It’s powerful, dextrous and sensitive enough that an operator can:

Manoeuvre objects from 10kgs (one arm) to 100kgs (two arms with crane attachment)

Dispense one drop at a time from a standard pipette

Detect the different textures of surrounding surfaces.

Specifically designed to replicate human arms

The human operator can prepare for tasks and carry them out almost exactly as if they were intervening in the environment directly. Almost exactly, because the operator’s capabilities are enhanced by Dexter’s power, adaptability.

Dexter makes complex work simpler

Dexter can operate hand tools that a human can, and over 2,000 tools have been adapted for the manipulator, making it possible to deal effectively with the unexpected in a remote environment. Dexter allows operators to do more than they could unaided, for example with measures that reduce fatigue and increase sensitivity.

From its adjustable force-scaling to its ergonomic seated or standing operating positions, Dexter has been designed to make complex remote handling work simpler.

Dexter in action

Investigate after reactor core meltdown

Client: Mitsubishi Heavy Industries

Project objective: To investigate the site status after Fukushima reactor core meltdown

Operators use Dexter to support the main robotic investigation boom:

Change inspection equipment on the boom that enters the reactor

Post equipment into and out of the container where the boom is housed

Operate tools inside the boom container

Dexter Solution Key Benefits:

Risk reduction and complex task simplification in high hazard environment

Ability to deal safely with the unexpected by having a “human in the loop”

Improved operational efficiency through increased asset utilization

Simplification of glovebox and protection systems

Up-skilling of workforce